Lenovo has recently announced they had developed a new patent-pending, Low Temperature Solder (LTS) process to improve PC manufacturing while conserving energy and increasing reliability. This will drastically reduce carbon emissions by an estimate of 35%, as well as improving power consumption and reduce heat thru an improved tin-based solder process which replaces the older lead-based process. This new manufacturing process can be universally applied to all electronics manufacturing that involves printed circuit boards, with no cost or performance impact to customers.

While traditional tin-based solder process required extremely high temperatures, consuming more energy and adding significant stress on components, with the new LTS process, soldering heat is applied at maximum temperatures of 180 degrees Celsius, which is a reduction of 70 degrees from the previous method. Throughout testing and validation, Lenovo used existing materials to compose the solder paste and existing oven equipment for heating, thus implementing the new system without any increase in production costs.

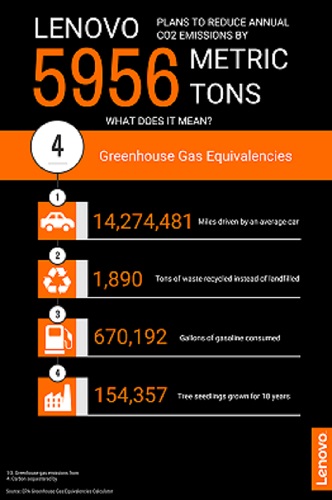

After validation of the procedure, Lenovo discovered that significant amounts of carbon emission is reduced as a result of using this new process. The procedure is already in production for the ThinkPad E series and the 5th generation X1 Carbon that was recently announced at CES. Lenovo intends to implement the new LTS process on 8 SMT lines in 2017, and estimates carbon emissions savings of up to 35%! Lenovo aims to have 33 SMT lines with 2 ovens per line using this new process by the end of 2018, giving an estimated annual saving of 5,956 metric tons of CO2, which, when put into perspective, is equal to the consumption of 670,170 gallons of gasoline per year.

Lenovo also expects better reliability for its devices through the new process, due to lower heat stress during the “oven bake” procedure. Lenovo has observed a 50% decrease in printed circuit board warpage, as well as a reduction in defective parts during the manufacturing process in the early stages of deployment.

“By implementing the new LTS process, Lenovo is continuing to show its commitment to upholding sustainable business practices across its PC business. Our focus on innovation extends beyond R&D and product design, to the way our products are manufactured. We are dedicated to advancing our business goals while reducing our impact on the environment and we’re proud this process achieves that,” said Luis Hernandez, vice president, Lenovo PC and Smart Devices Integrated Development Center.

Lenovo intends to offer the new procedure for use on an industry-wide basis in 2018, free of charge, thus proving its commitment in supporting a transition to a lower carbon economy thru the savings the new LTS process brings.

[Source]

COMMENTS